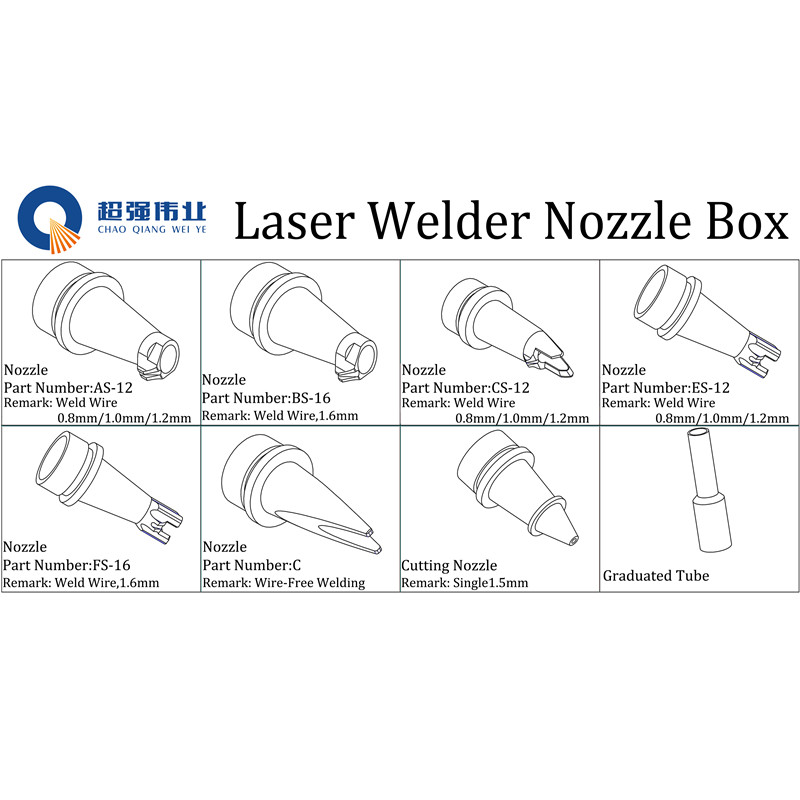

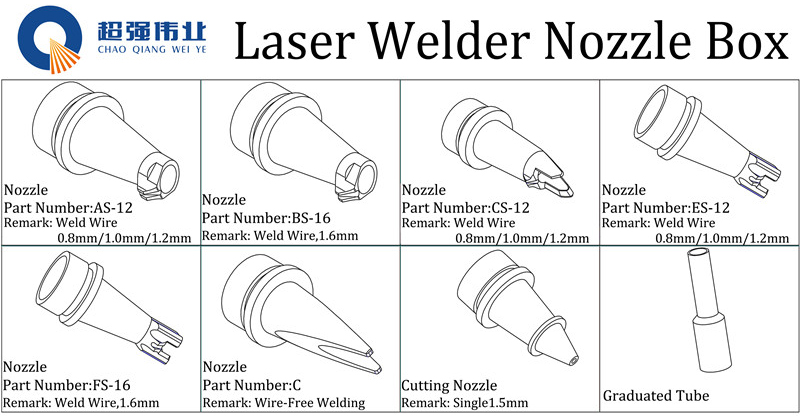

Nozzle na Copper don Shugaban walda

Sashe na lamba: AS-12

Bayani: Weld Waya 0.8mm/1.0mm/1.2mm

Lambar Sashe: BS-16

Bayani: Weld Waya, 1.6mm

Lambar Sashe: BS-16

Bayani: Weld Waya, 1.6mm

Lambar Sashe: ES- 12

Bayanin Weld Waya 0.8mm/1.0mm/1.2 nm

Lamba: FS- 16

Bayani: Weld Wire, 16mm

Lambar Sashe: C

Bayani: Waya - Waya Kyauta

Lambar Sashe: C

Bayani: Waya - Waya Kyauta

Lambar Sashe: C

Bayani: Waya - Waya Kyauta

Tube Graduated

Tasiri na bututun ƙarfe na Laser sabon na'ura a Laser sabon?

Laser sabon na'ura da ake amfani da lalle za ta yi amfani da bututun ƙarfe, kasuwa ne yafi raba zuwa supersonic bututun ƙarfe da subsonic bututun ƙarfe, supersonic kamar yadda sunan yana nuna cewa iskar gas ya fi girma da sauri na sauti, subsonic bututun ƙarfe ne gas kwarara kudi ne m. fiye da saurin sauti.An raba nozzles guda biyu zuwa m da ma iri biyu.Bari mu dubi tasiri na bututun ƙarfe na Laser sabon na'ura a lokacin da Laser sabon.

Dual Laser sabon na'ura

Kafin ka ce bututun Laser sabon na'ura yana da tasiri a kan yankan Laser, da farko ka ce gas na taimako yana taka rawa wajen yankewa.Na farko, hanzarta yanayin sanyaya na yanki, rage yankin da ya shafa zafi, da kuma taimakawa wajen samar da wuri mai santsi.Na biyu, iskar oxygen a matsayin iskar gas na iya ƙara yawan zafin jiki, mafi dacewa ga yankan faranti mai kauri.Na uku, inert gas a matsayin karin gas iya hana workpiece hadawan abu da iskar shaka, kula da halaye na kayan da kanta.

1. Tasirin danko oxide

Daga cikin dukkan sigogin fasaha na yankan Laser, matsi na gas na taimako da halayen kwararar gas sune mahimman abubuwan da ke shafar ingancin yanke.Lokacin yankan faranti mai kauri, irin su carbon karfe, ana amfani da iskar oxygen azaman iskar gas domin baƙin ƙarfe oxides yana da ɗan ɗanko kaɗan kuma yana da sauƙin cirewa daga yanke.

A karkashin yanayi na al'ada, ko da yake gefen carbon karfe Laser yankan incision ya ƙunshi bakin ciki Layer na baƙin ƙarfe oxide, a mafi yawan lokuta, ingancin Laser yankan carbon karfe sabon surface ne m.Amma saboda bakin karfe yana ƙunshe da chromium, kuma narkakkar chromium oxide yana da ɗanko mai yawa, mai sauƙin haɗawa a bangon gefen incision, don haka amfani da iskar oxygen iri ɗaya azaman iskar gas mai ƙarfi, ingancin sarrafa bakin karfe ya fi carbon karfe muni.Idan matsin iskar gas ba shi da yawa, yana da wuya a cire waɗannan oxides.

Haka matsalar za ta faru a lokacin da yankan aluminum da titanium gami, domin narkakkar aluminum da titanium oxide suma suna da danko mafi girma, domin samun kyakkyawan yankan ingancin dole ne ya buƙaci ƙarin matsin lamba na iskar gas.A gaskiya ma, Cr, Al, Ti alloys suna da wuyar yanke kayan.

Nunin fasahar yankan yankan Laser

2. Tasirin danko na slag a cikin yanayin narkewa

Yanke Laser tare da iskar gas a matsayin karin gas na iya rage tasirin matsalolin da ke sama zuwa wani matsayi, amma iskar gas yawanci yana buƙatar yin aiki a cikin kewayon matsi mai tsayi na 8 zuwa 25Bar, kuma za a iya ɗaukar narkakken ƙarfe a cikin incision. a ƙarƙashin aikin ƙarfin iska mai ƙarfi.Domin babu iskar oxygen a cikin kwarara, karfe oxides ba zai samu a cikin yanke.Gabaɗaya, tsaftataccen ƙarfe a cikin narkakken ƙasa yana da ɗanɗano kaɗan fiye da oxide ɗinsa kuma ana iya busa shi cikin sauƙi, don haka yana da sauƙi a samar da ƙaramin yanki da zafi ya shafa da wuri mai santsi ba tare da ƙazantar oxide ba.

Tsarin musamman na bututun ƙarfe na supersonic na iya kusan canza matsa lamba na iskar gas ɗin zuwa makamashi mai ƙarfi, busa slag, da cimma cikakkiyar yankan Laser.